Ramina Plastic

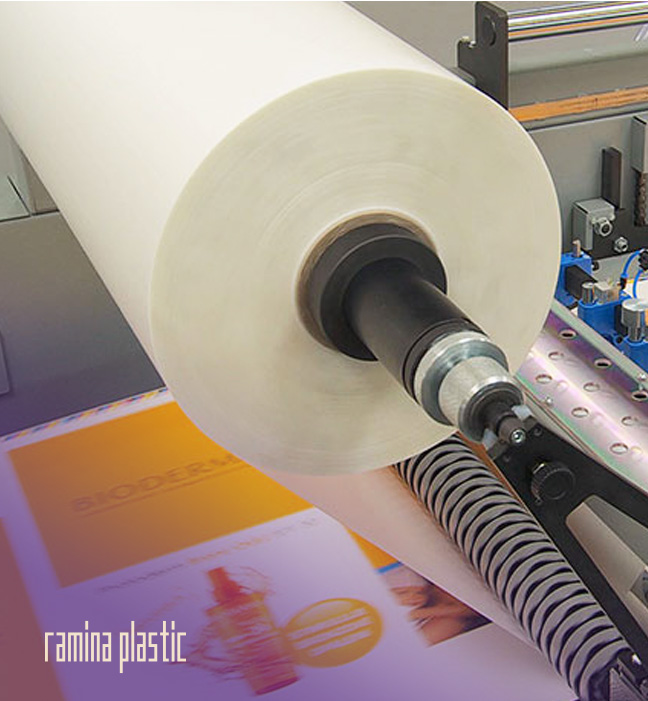

Due to the difference in polymer properties in different types of polymer films, manufacturers combine the properties of different polymer and polypropylene films through the lamination process to achieve properties such as high stitchability, print quality, resistance to oxygen penetration and They laminate two or three layers of film.

In the following, we will introduce the types of laminate.

– Non-solvent laminate

– Solvent laminate

Non-solvent laminate

This type of lamination is done using dry glue without solvent, which is suitable for laminating two layers of polymer film. Since the smell of solvent and problems of its vapors are eliminated in this laminate system, it is a very suitable option for laminating wrappers used in food and pharmaceutical industries.

For example, structures:

BOPP/BOPP (transparent, opaque, metallized and prealized) is used for packing food with low volume such as cakes and cookies, pasta, flour, snacks, chips, etc.

This machine is capable of laminating up to a maximum width of 115 cm and the sewing temperature is between 150 and 180 degrees Celsius.

solvent laminate

This process has the ability to laminate two or more layers of polyethylene-trisbaphone (BOPP)-paper and aluminum materials using solvent.

– Sewability at high temperature

– The possibility of laminating products with acidic and alkaline properties

– The maximum width of 110 cm is one of the advantages of solvent laminate.

Printed laminated films with polyester/polyethylene structure (PET/PE) for use in pizza cheese envelopes, vacuum envelopes, three-sided stitching and eight-sided stitching and…

The structure of polyester/metallized polyester/polyethylene (PET/PET/PE) in the packaging of yogurt, sauce, coffee, cosmetics and…

And also the structure of polyester/paper/polyethylene for use in packing tea, soap, etc.

PET/CPP structure suitable for flooding on containers and thermoforming machine are laminated using this machine.

Polyester is in great demand for its use in food and perishable packaging due to its high barrier properties against the penetration of oxygen, because polyester film is effective in increasing the expiration time of the product. Also, polyester films have high resistance. They show themselves against all kinds of scratches, in addition to having high strength and high temperature does not damage them.